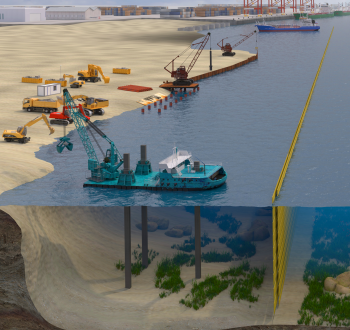

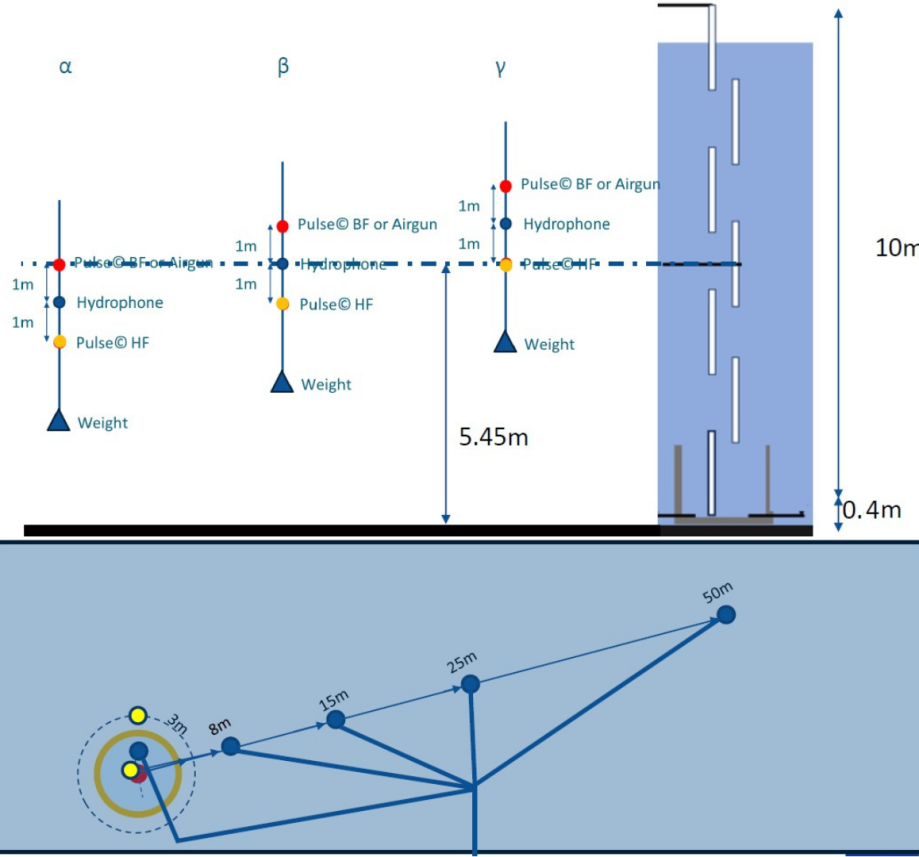

- A modular design to adapt to multiple configurations of type of works and maritime conditions

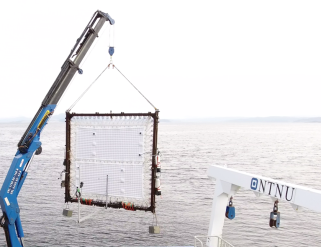

- An installation that does not require heavy means, nor extra cranes or vessels

A technical innovation

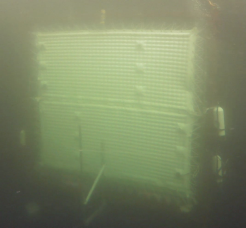

The SubSea Quieter membrane is the “double glazing principle” adapted to maritime constraints:

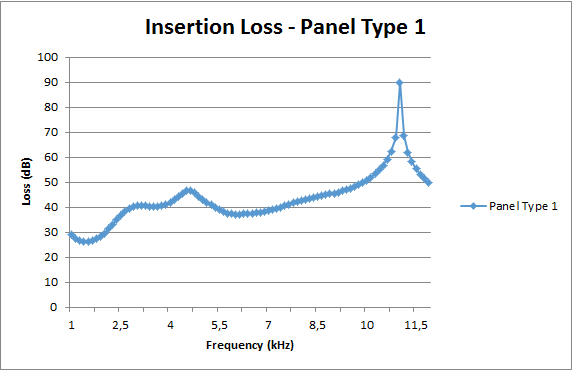

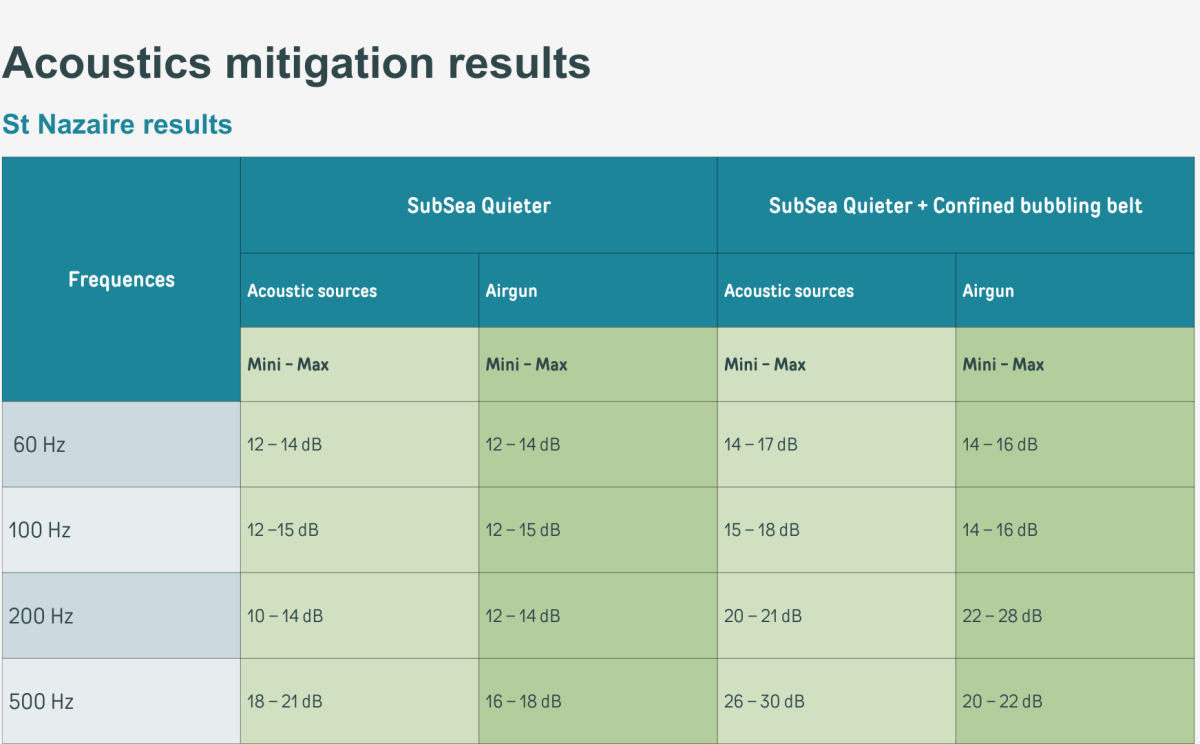

- An underwater noise reduction between 10 and 45 dB depending on frequencies.

- A solution with a double capacity: noise mitigation system and barrier against turbidity

- A system designed and tested to resist maritime constraints: swell, currents, pressure, corrosion